Reliable level measurement for barges - Part 2

Magnetostrictive measurement principle

The absolute, liquid level transmitters provided by Temposonics rely on the company’s proprietary magnetostrictive technology, which can determine position with a high level of precision and robustness.

Each liquid level transmitter consists of a ferromagnetic waveguide, a float with an internal magnet, a strain pulse converter and supporting electronics. The magnet, contained inside of the float that rides on the liquid, generates a magnetic field at its location on the waveguide. A short current pulse is applied to the waveguide. This creates a momentary radial magnetic field and torsional strain on the waveguide. The momentary interaction of the magnetic fields releases a torsional strain pulse that propagates the length of the waveguide. When the ultrasonic wave reaches the end of the waveguide it is converted into an electrical signal. Since the speed of the ultrasonic wave in the waveguide is precisely known, the time required to receive the return signal can be converted into a linear position measurement with both high accuracy and repeatability.

Each liquid level transmitter is custom built to the tank. The level transmitter consist of a pipe, sensing element, float, housing, and electronics. The pipe is order according to the the height of the tank and isolates the sensing element from the process. The sensing element determines the liquid level in the tank using the magnetostrictive principle mentioned above and the permanent magnet located inside of the float. The housing protects the electronics from the external environment and the electronics process the measurement by the sensing element and provide the needed output for the control system.

To compensate volume fluctuations due to varying temperatures, the sensors also contains a temperature probe for measurement of the liquid temperature. As this probe is fitted in the sensor pipe as well, only a single opening in the tank is required to measure the level and the temperature.

Onsite display of the Level Plus® Transmitter (source: ITU).

Modular construction facilitates the installation

A particular advantage of the Level Plus® liquid level transmitter is the simple, modular construction that enables the device to be installed or removed quickly. After installation, the sensor pipe is an integral part of the tank whereas the electronics and sensing element can be removed. In the event of maintenance, the tank is in operation when the level transmitter is serviced. Expensive discharge of the liquid and gas drainage are not necessary. This is important for closed tanks with gas recirculation, as found on gas tankers. Within a few minutes, a new electronic and/or waveguide can be mounted in the existing pipe – completely without calibration.

Without re-calibration

As the operation of the magnetostrictive measuring principle is independent of the properties of the loaded product (e.g. dielectric constant, temperature, etc.), calibration or re-calibration are unnecessary. Unlike other technologies, Level Plus® liquid level transmitters do not require re-calibration throughout their useful life. Even after interrupting the operation, re-adjustment is not necessary: The magnetostrictive principle provides absolute level measurement. After re-starting, the measuring signal is immediately available again. Once installed and put into operation, the sensors operate without the need for maintenance.

Reliable operation under extreme conditions

Level Plus® liquid level transmitters are able to withstand the most severe environmental conditions. Within a temperature range of -40 to +150°C, maximum pressure of 69 bar, and order length up to 22 m they provide reliable level measurement across various applications. Turbulence, foaming, gas layer or vapours do not falsify the signal. The LP-Series are IECEx and ATEX approved for installation in Zone O and 1 of hazardous areas with intrinsically safe or flameproof certification.

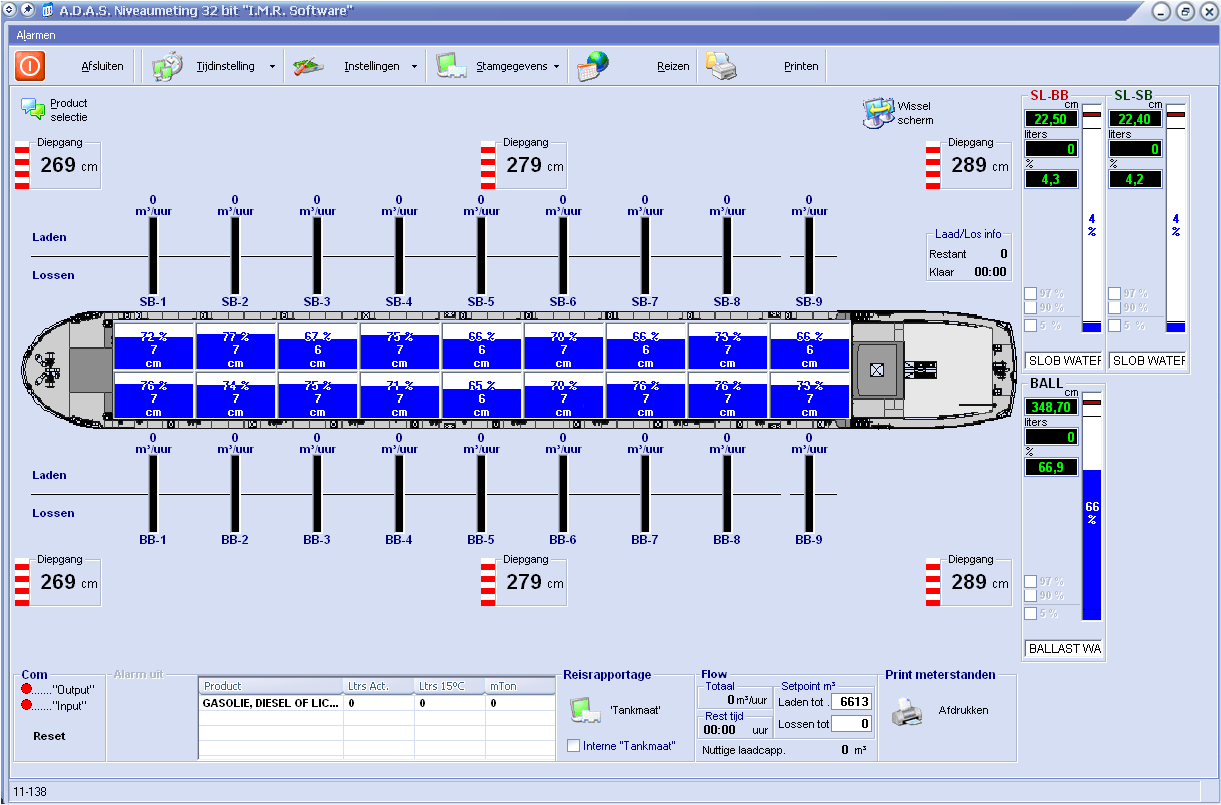

General overview of level measurement on the Commodore II (source: ITU).

High repeatability and accuracy

Equipped with Temposonics liquid level transmitter and ITU control instrumentation, tankers reach high accuracy of the load management. And Marcel Idsinga confirms: “With Temposonics, we have installed products featuring the highest precision offered in the market. Our experiences as well as the customer feedback show that the delivered measuring value is substantially better than the deviation of mostly 0.2 % accepted by the oil companies.”

Apart from the exact determination of the load volume, mainly the high repeatability of the sensors is an important plus for the ship operator. Owing to the high repeatability of the Level Plus

® sensors, the measurement error – which cannot be reduced any further – remains constant and consequently calculable at each load or discharge operation.

From practical experience, managing director Marcel Idsinga knows: “Magnetostrictive sensors are generally known for their accuracy and repeatability. Measured values from these sensors are accepted for goods exchange by loaders, operators and load owners.” The operator can display the volume from the A.D.A.S. software and compare it to the quantity specified by the loader or the unloading point. In case of deviations, a complaint is based on an accurate, reliable measured value. Even low volume variations need not be accepted.

Decisive cost advantages

All aspects considered, tankers equipped with Level Plus® liquid level transmitters are cost saving both for owners and operators. The operating costs for level measurement are very low throughout the lifetime of the tanker. Quick commissioning and easy sensor servicing as well as elimination of the need for calibration ensure smooth operation. The investment costs pay off quickly thanks to reduced maintenance expenditure and shorter downtimes. Moreover, exact and reproducible measurement results reduce the volume error, which does not reduce the operator’s profit. Marcel Idsinga concludes: “Temposonics are a cost-efficient level measurement solution for the entire lifecycle of the tanker.”

Temposonics Level Plus® Füllstandsmesser Installation.

GET IN TOUCH WITH US

You have a question about one of our products or would like more details on a possible application?

Click here to fill in our request form

Don't want to miss out on the latest blog updates and other news?

Click here to subscribe to our newsletter

Total customer satisfaction

We live by the promise of unparalleled service that

enables us to take all available means to exceed your expectations.

Click here to find out how we support our customers